Why PVC Is a Dangerous Gamble

PVC piping may seem like a budget-friendly option for compressed air systems, but it poses serious safety risks. Learn why aluminum—especially AIRpipe’s modular systems—is the safer, compliant, and future-proofed solution for industrial environments.

In 2021, a Midwest auto shop suffered $20,000 in damages when a PVC air line ruptured—sending shards across the workspace and injuring two technicians. The culprit? A material never designed for compressed air. PVC may seem cheap and convenient, but it’s a ticking time bomb in high-pressure environments. Cheap and easy now could turn into expensive and deadly down the road.

In 2021, a Midwest auto shop suffered $20,000 in damages when a PVC air line ruptured—sending shards across the workspace and injuring two technicians. The culprit? A material never designed for compressed air. PVC may seem cheap and convenient, but it’s a ticking time bomb in high-pressure environments. Cheap and easy now could turn into expensive and deadly down the road.

PVC’s appeal is obvious: it’s inexpensive, lightweight, and easy to install. But those surface-level benefits collapse under the pressure of real-world use. Compressed air systems generate heat, oil vapor, and pressure spikes—conditions PVC was never designed to handle.

Even at just 110°F, PVC’s pressure rating drops by half. And with small piston compressors often pushing air at 200°F or more, failure isn’t a question of “if”—but “when.” Add in exposure to oil mist and UV light, and PVC becomes brittle, unpredictable, and dangerous.

A PVC pipe cracking or failing at 100 psi can easily injure you or your employees.

If you’re considering PVC for your shop or facility, it’s time to reconsider.

The risks are real, and the consequences can be catastrophic.

Safety and Performance:

Choosing The Right Material

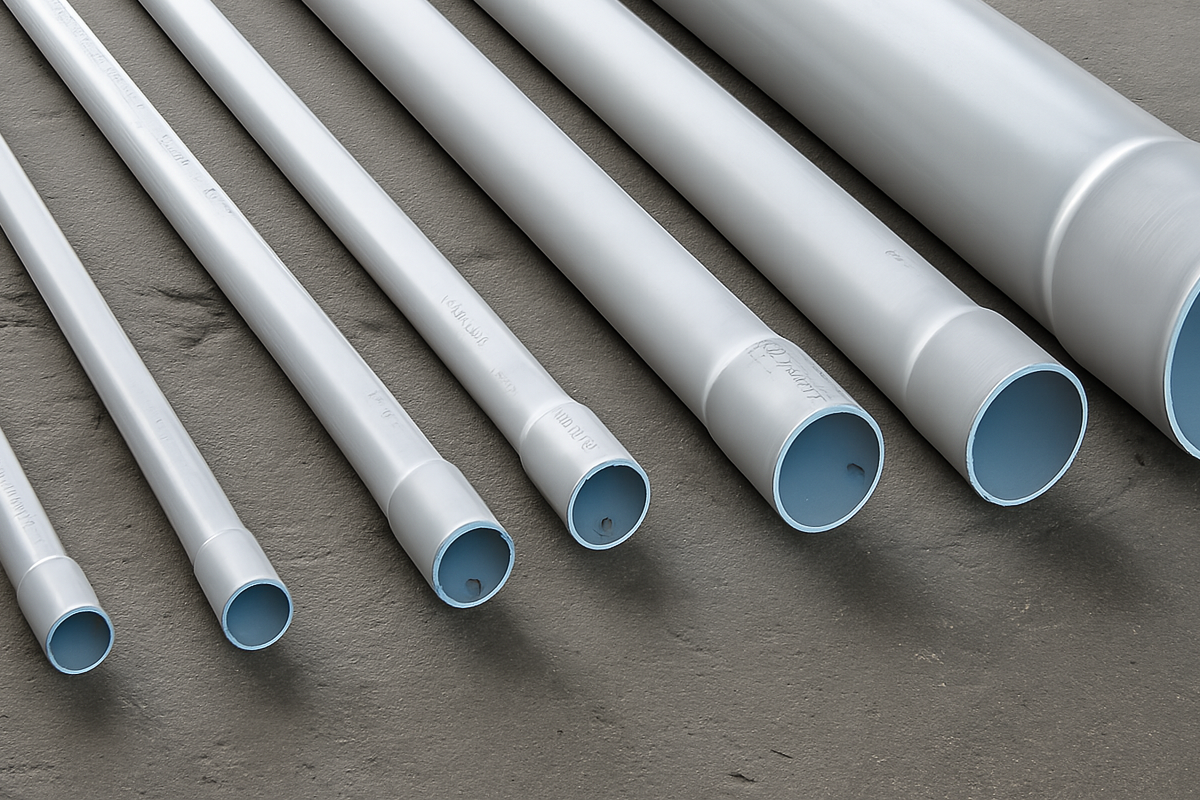

Aluminum isn’t just a better alternative—it’s engineered for compressed air. AIRpipe’s aluminum systems deliver unmatched safety, performance, and scalability.

Aluminum isn’t just a better alternative—it’s engineered for compressed air. AIRpipe’s aluminum systems deliver unmatched safety, performance, and scalability.

Aluminum alloys handle elevated temperatures without degrading, making them ideal for high-pressure environments. They’re lightweight yet incredibly strong, with a superior strength-to-weight ratio that ensures long-term reliability.

Unlike PVC, aluminum won’t crush or shatter under stress—and it resists corrosion naturally, thanks to its protective oxide layer.

AIRpipe’s modular design simplifies installation and future upgrades.

Quick-connect fittings eliminate the need for glue or threading, and directional flow options make system expansion intuitive and efficient. In the long run, aluminum pipe can be the better cost-effective and versatile compressed air pipe system for your garage, shop, or warehouse.

Avoiding Pipe Failure:

PVC vs Aluminum

AIRpipe systems are built for safety and efficiency. Fewer leaks, faster installs, and easier expansions—without the risks associated with PVC. Here’s a quick comparison of key performance and safety factors:

- PVC fails explosively under pressure, sending dangerous shards across the workspace

- PVC becomes brittle from heat, oil vapor, and UV exposure—leading to sudden rupture

- PVC loses half its pressure rating at just 110°F, making it unreliable in real-world conditions

- Aluminum resists heat, corrosion, and chemical breakdown.

- AIRpipe’s modular system reduces energy loss and simplifies maintenance.

- Aluminum piping meets industrial safety standards and audit requirements.

Choose Compressed AIR Piping Wisely:

Upgrade To Aluminum

PVC might seem like a budget-friendly solution, but it’s a dangerous compromise. The risks—explosive failure, injury, liability—far outweigh the upfront savings. Aluminum, especially through AIRpipe’s modular systems, offers a future-proofed, audit-ready solution that protects your people and your productivity. If you’re planning a compressed air system, don’t gamble with PVC. Choose aluminum. Choose safety. Choose AIRpipe. Need help choosing compressed air piping? We are here to help. Just call.

Compressed Air Safety Resources

Compressed Air Best Practices Magazine

OSHA Compressed Air Guidelines